בתעשיית התיקים, פוליאסטר וניילון הם שני חומרי הבד הסינתטיים הנפוצים ביותר. מתיקי גב יומיומיים ותיקים מודפסים אופנתיים ועד תיקי נסיעות גדולים ותרמילי גב לטיולים, שני החומרים חיוניים. למרות שהם נראים דומים ויש להם פונקציות חופפות, אנשי מקצוע רבים בתעשייה וצרכנים נוטים לבלבל בין השניים. הבחנה נכונה בין פוליאסטר וניילון היא לא רק קריטית לבקרת עלויות, אלא גם משפיעה ישירות על ביצועי המוצר, מיצוב המוצר ותחרותיותו בשוק. מאמר זה יציג שיטה קלה להבנה ומעשית להבחנה בין שני בדים אלה.

בבחירת חומרים לייצור תיקים, החשיבות המרכזית של ההבחנה בין פוליאסטר לנילון טמונה בהתאמת החומר לדרישות השימוש הספציפיות. שני הבדים נבדלים באופן משמעותי מבחינת חוזק, עמידות בפני שחיקה, תחושה, עמידות למים ומחיר. זיהוי ברור של החומר מסייע במניעת בעיות כמו "איכות מטעה" או "צרכים לא תואמים".

פּוֹלִיאֶסטֶר: יש לו קשיחות וקשיחות טובות, עמיד בפני קמטים, והוא זול יותר. זוהי הבחירה המיינסטרימית עבור תיקי נסיעות, תיקים אופנתיים וטרנדיים ותיקים ידידותיים לתקציב.

ניילון: יש לו חוזק מתיחה גבוה יותר, עמידות מעולה בפני שחיקה בהשוואה לפוליאסטר, ומגע רך ועדין יותר. הוא מתאים לתיקי עסקים יוקרתיים, תיקים עמידים לשימוש חיצוני ותיקי נשיאה רכים.

זוהי שיטת ההבחנה המהירה הנפוצה ביותר בקרב אנשי מקצוע בתעשייה, שאינה דורשת כלים. היא מאפשרת שיפוט ראשוני באמצעות מגע ותצפית, מה שהופך אותה למתאימה לתרחישי בחירת חומרים ובדיקה באתר.

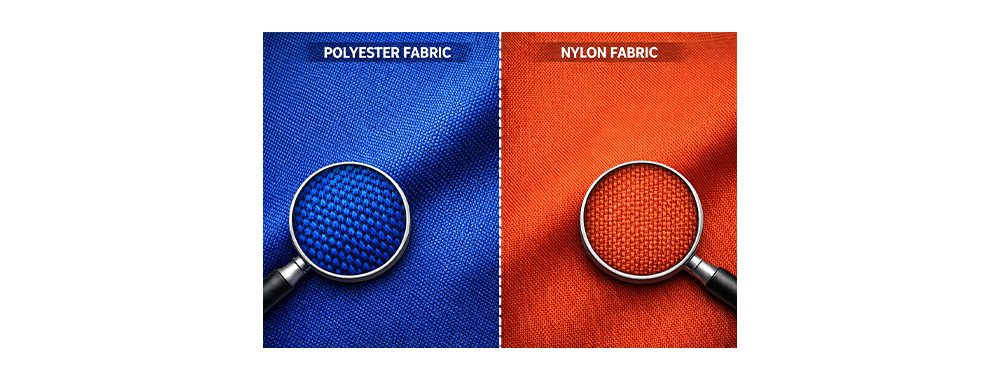

מנקודת מבט של מראה וברק;

בד פוליאסטר: החזר הפוליאסטר הוא רק כ-0.4%, החוטים נשארים יבשים ונוקשים, ומרכזים את ההשתקפויות לנקודות סיכות בהירות. הברק בהיר ונוקשה יותר, בדרך כלל עם ברק דמוי מראה. חלק מבדי הפוליאסטר באיכות נמוכה יותר עשויים אף להציג "ברק פלסטיק זול". פוליאסטר הוא נוקשה; לאחר קמט, קיפול חד אחד והוא מטיל פסים בהירים-כהים לסירוגין של בוהק מוחזר.

בד ניילון: עם החזרת לחות של כ-4%, סיבי הניילון מתנפחים מעט, הבורות המיקרוסקופיים על פני השטח מתיישרים, והאור משתקף באופן שווה, ומעניק ברק משיי, כמעט שומני. הברק רך ומעודן יותר, עם אפקט פנינה קל. במיוחד תחת אור, הוא אינו נראה בוהק אלא נותן מרקם עדין וחלק. הניילון רך ומתעוות מעט תחת לחץ, כך שהברק שלו נשאר קבוע, לעולם לא מהבהב בין בהיר לעמום.

עבור בדים בעלי אותו מפרט, מנקודת מבט של מראה ומרקם;

בד פוליאסטר: הסיבים גסים יחסית, עם מרווחים מעט רחבים יותר בין המרקמים, במיוחד בבדים "דנייר" שבהם המרקם בולט יותר, ומעניק מראה "מחוספס" יותר.

בד ניילון: הסיבים דקים יותר והמרקם צפוף יותר. כאשר מסתכלים עליו בעין בלתי מזוינת, הבד נראה "עדין" ומעודן יותר.

עבור בדים בעלי משקל ומפרט זהים;

בד פוליאסטר: תחושת היד יחסית נוקשה ומובנית, עם חלקות מעט נמוכה יותר. בעת כיווץ, יש התנגדות מורגשת, וחלק מבדי הפוליאסטר עשויים אף להיות בעלי "תחושה פלסטית" קלה.

בד ניילון: תחושת היד רכה ועדינה יותר, עם רמה גבוהה יותר של חלקות. כאשר מכווצים, יש התנגדות מועטה, מה שנותן תחושה "משיית", והוא אינו מרגיש מחוספס על העור.

כאשר כווץ אותו בכוח;

בד פוליאסטר: הסיבים קשיחים יותר, עם חיכוך חזק יותר ביניהם, מה שיוצר צליל חד ופריך יותר ותחושת חיכוך בולטת יותר.

בד ניילון: הסיבים רכים יותר, והמשטח חלק יותר יחסית. צליל החיכוך בין הסיבים נמוך וקצר יותר.

לאחר קיפול;

בד פוליאסטר: הוא יוצר בקלות קמטים עמוקים, ובשל גמישותו המוגבלת, הקמטים אינם ניתנים להעלמה בקלות.

בד ניילון: הוא מתאושש במהירות למצב חלק, כך שהקמטים שנותרים מאחור הם בדרך כלל רדודים או אפילו בקושי מורגשים.

אם לא ניתן לקבוע את החומר באמצעות השיטות האינטואיטיביות לעיל, ניתן להשתמש בבדיקות פיזיקליות, שריפה או כימיות פשוטות לאימות נוסף.

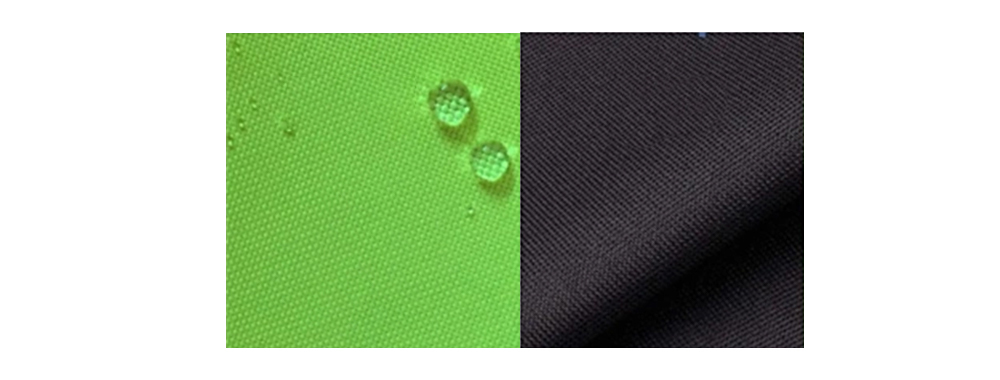

גם פוליאסטר וגם ניילון הם סיבים הידרופוביים, כלומר יש להם ספיגת מים נמוכה. עם זאת, לניילון יש קצב ספיגת מים מעט גבוה יותר בהשוואה לפוליאסטר. ניתן לבדוק זאת על ידי לקיחת דגימת בד קטנה, הנחת 1-2 טיפות של מים נקיים עליה, והתבוננות בהתנהגות טיפות המים.

בד פוליאסטר: טיפות מים יישארו על פני הבד למשך זמן רב, ויצרו אפקט של "גלגול חרוזים". מים מתקשים לחדור, וגם אם כן, זה לוקח יותר זמן. הסימנים הכהים באזור הספוג במים אינם מורגשים במיוחד.

בד ניילון: טיפות מים יחדרו באיטיות לתוך הבד, והאזורים הספוגים במים יראו סימנים כהים קלים. מהירות החדירה מהירה יחסית.

בתעשיית התיקים, עמידות הבד לשחיקה היא קריטית, ועמידות הניילון לשחיקה עולה בהרבה על זו של פוליאסטר. ניתן לאמת זאת באמצעות "מבחן חיכוך": קחו שתי דגימות בד מאותו מפרט ושפשפו אותן על משטח מחוספס בעוצמה במשך 10-20 פעמים. לאחר מכן, התבוננו בבלאי ובקרע של הבד. דגימת הניילון בדרך כלל תראה פחות נזק, בעוד שדגימת הפוליאסטר עשויה להראות יותר סימני שחיקה.

בד פוליאסטר: לאחר חיכוך, פני השטח נוטים להראות פילינג קל או התפוררות, והמרקם הופך מטושטש. רמת הבלאי גבוהה משמעותית מזו של ניילון.

בד ניילון: לאחר חיכוך, פני השטח מראים מעט מאוד פילינג או אפרפרות, והמרקם נשאר נקי. הבלאי מינימלי.

מאפייני הבעירה של סיבים סינתטיים הם המפתח להבחנה בין חומרים, וההבדלים בהתנהגות הבעירה בין ניילון לפוליאסטר ניכרים למדי.

בד פוליאסטר: כאשר היא נדלקת, הלהבה צהובה, והיא נמסה לטיפות תוך כדי הבעירה, מלווה בריח שריפה פלסטי מובהק. הטיפות מתקררות לחלקיקים שבירים שנשברים בקלות כשלוחצים עליהם. במהלך הבעירה נוצרת כמות קטנה של עשן שחור, ולאחר שהלהבה כבתה נותרת כמות קטנה של אפר אפרפר-לבן.

בד ניילון: כאשר היא נדלקת, הלהבה כחולה, והיא נמסה לטיפות עם ריח קל של סלרי או צמר. הטיפות מתקררות לחלקיקים שחורים קשים וחלקים שאינם נשברים כשלוחצים עליהם. לא נוצר עשן שחור משמעותי במהלך הבעירה, ואין שאריות לאחר שהלהבה כבתה.

אם הלקוח מציין חומר ניילון ובדיקת הבעירה מעוררת ספקות, ניתן להשתמש בשיטה זו: הכינו תמיסת חומצה הידרוכלורית מדוללת בריכוז 5%, טפטפו טיפה אחת על הבד וצפו בתגובת הבד.

פּוֹלִיאֶסטֶר: לאחר 5 דקות של חשיפה, הוא נשאר שלם, עם רק התעקלות קלה של פני הבד.

ניילון: תוך 30 שניות, הסיבים מתפרקים, וחורים גלויים מופיעים על פני הבד.

ההיגיון המרכזי להבחנה בין בדי פוליאסטר לנילון הוא כדלקמן: ראשית, יש לבצע שיפוט ראשוני באמצעות השיטות האינטואיטיביות, ולאחר מכן לאמת את החומר באמצעות בדיקות פשוטות. על ידי שילוב שתי הגישות הללו, שיעור הדיוק יכול להגיע כמעט ל-100%.

הנה כמה המלצות מעשיות לקבוצות שונות של אנשים;

1. לאנשי מקצוע בתעשיית התיקים (מעצבים, רכשים וכו'): מומלץ לתעדף את בדיקת הבעירה ובדיקת העמידות בפני שחיקה כדי לאשר את החומר. בנוסף, יש לשלב את דוח הבדיקה של ספק הבד כדי להימנע מרכישת חומר שגוי.

2. עבור צרכנים כלליים: אין צורך לבצע את בדיקת הבעירה. פשוט השתמשו בתחושה המישוש: "רך וחלק = ניילון, נוקשה ופלסטיק = פוליאסטר", לצורך שיפוט אינטואיטיבי. לאחר מכן, שקלו את המחיר והמיקום של התיק כדי לענות על צרכי הרכישה.

לסיכום, למרות שפוליאסטר וניילון הם שני בדים הנפוצים בייצור תיקים ונראים דומים, הם נבדלים באופן משמעותי בתכונות הליבה ובתרחישי היישום שלהם. עבור אנשי מקצוע בתעשיית התיקים, שליטה בהבחנה בין השניים היא קריטית. בין אם מדובר בתרמיל גב קל ועמיד לנסיעות יומיומיות, תיק נסיעות לחוץ המדגיש חוזק ועמידות בפני שחיקה, או תיק יד אופנתי המתמקד במרקם וקשיחות, בחירת החומר הנכון משפיעה ישירות על ביצועי המוצר וחוויית המשתמש. הבנת ההבדלים הללו מאפשרת בידול מדויק במהלך הפיתוח, הרכש או בקרת האיכות, מונעת טעויות בבחירת חומרים ומשפרת את התחרותיות של מוצרי תיקים בשוק.

| מְחַבֵּר | ||||||

|

זכויות יוצרים

@2024 Synberry Bag & Package Products Co.,Ltd כל הזכויות שמורות

.

רשת נתמכת

רשת נתמכת

מפת אתר / בלוג / Xml / מדיניות פרטיות